FAQ

Have Questions?

As electrical demand grows across every sector, earthing has evolved into a vast and critical subject. Yet, it remains one of the most overlooked aspects of electrical safety. Our FAQ section addresses the most common questions and misconceptions about earthing, helping engineers, builders, and decision-makers understand its vital role in protecting lives, equipment, and systems.

Earthing provides a safe path for fault or leakage current to flow into the ground. It prevents electrocution, equipment damage, and electrical fires by stabilizing voltage and safely discharging unwanted current.

Because electricity follows Ohm’s Law (V = I × R) and always flows where resistance is lowest. If earthing is good (low resistance), current safely goes into the ground. If the earth resistance is high, fault current may travel through people, buildings, or equipment—causing death, injury, or fire.

- Fault current may not flow properly into the ground.

- It may cause dangerous voltage build-up.

- Can lead to electric shock, fire, or failure of safety devices (MCBs, ELCBs).

Regulatory non-compliance and insurance claim rejection in case of fire/electrical failure.

Depends on application:

- <1 Ohm → Substations, data centers, critical plants

- <2 Ohm → DG, Transformer, Electrical Telecom, commercial buildings

- <5 Ohm → Homes, Industrial Plant, non-critical installations

- <10 Ohm → TFR for Electrical, Telecom, LPS Towers

Lower is always better and more stable.

- If the soil is dry, rocky, or sandy.

- If you need stable resistance value.

- If you want no water, no refilling, no replacement, no maintenance at site.

- If you need 25+ years performance warranty.

If YES → Conductive Concrete Earthing is the best solution.

These materials may give temporary low resistance, but: • Need water refilling • Degrade over time • Corrode electrodes • Are not certified or eco-safe in many cases.

Ask for:

• IEC 62561-7 test report

• Material Safety Data Sheet (MSDS)

• Soil resistivity and resistance test reports

• Manufacturer’s certificate or performance warranty

• Project references or testimonials

❌ Skipping soil testing.

❌ Using uncertified chemicals.

❌ No performance testing after installation.

❌ No documentation for compliance.

❌ Ignoring resistance stability over time.

✔️ Consistently low resistance (<1 Ohm in critical zones)

✔️ Maintenance-free operation

✔️ Long life (30–50 years)

✔️ Safety for life, property, and equipment

✔️ Compliance with IS/IEC/IEEE standards

✔️ Full documentation, warranty, and test results

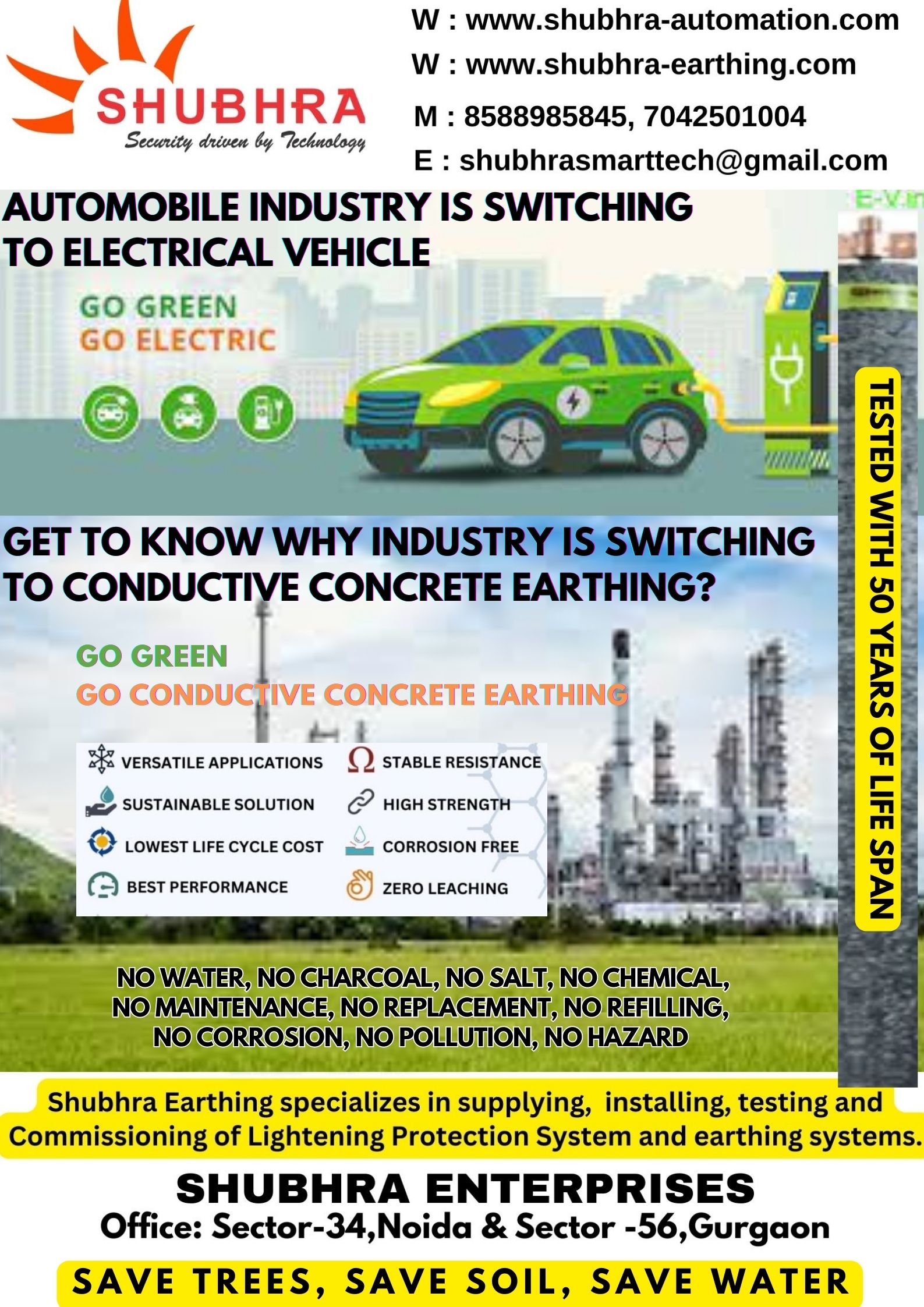

Conductive concrete earthing uses a special blend of concrete mixed with conductive materials (such as graphite, carbon, and metal oxides) that significantly reduce soil resistivity, creating a stable and long-lasting low-resistance path for fault currents.

Salt & charcoal are organic, and chemical based earthing are moisture-dependent materials that degrade over time. Conductive concrete, on the other hand, is inorganic, non-corrosive, and retains low resistance values even in dry conditions for decades.

Because of its long life, minimal maintenance, and excellent performance in high-resistivity soils, conductive concrete is now standard in critical infrastructure like data centers, hospitals, railways, and substations across India. It ensure uninterrupted operations, reduce maintenance, and meet international safety standards.

Absolutely. It provides stable, low earth resistance value, preventing dangerous step and touch voltages that often lead to electrocution accidents in traditional systems and consistent grounding for fault currents, avoiding arcing or overheating at poor grounding connections — a common cause of electrical fires in traditional earthing setups.

While the initial cost is higher, the lifetime cost is significantly lower due to zero maintenance, no refilling, and long service life. It’s a one-time investment with no recurring expenses. If the quantity is higher we can provide a price competitive to replace the other earthing with 5 to 8 years life span.

Yes. It can be used to upgrade or supplement existing earthing systems, especially where conventional systems have failed to meet resistance targets.

It’s being used in PowerGrid, DVC, A.P.Transco, KSEB, rail projects metro, DFCCIL, data centers, smart grids, NTPC, substations, Defence and solar farms, Helio’s Photovoltaic, Corporates, DS Group, U-Flex, TATA Steel Even BARC, ISRO and DRDO facilities are using it for critical applications.

Yes. Many CPWD, PWD, and state electricity board tenders now include enhanced or conductive concrete earthing as an approved alternative — especially in smart city, EV charging, and renewable energy projects.

Absolutely. No water, no salt, no recurring refilling, and no seasonal drop in performance. It’s the ideal “install-and-forget” solution for remote or unmanned installations (like solar projects, Transmission or telecom Towers).

Traditional methods depend on moisture retention, seasonal stability, and repeated maintenance. Bentonite swells and shrinks with moisture, and chemical systems leach over time. As India moves to 24×7 electrification and high-density power grids, these systems fail to maintain consistent resistance, leading to dangerous faults, fires, and electrocution risk

It complies with:

- IEC 62561 (earthing components)

- IEEE Std 80 (grounding in substations)

- EN 50522 (earthing of power installations)

- IS:3043 recommendations for low-resistance paths

As per NCRB and CEA reports:

- Over 10,000 electrocution deaths per year in India — highest in the G20.

- Fire accidents from electrical faults have increased over 30% in the past 5 years.

- 60% of these incidents are directly linked to poor or failed earthing systems.

✅ Countries like Germany, UK, and Japan have reduced such incidents drastically by switching to enhanced earthing systems like Conductive Concrete.

Chemical systems corrode electrodes by acidic leaching, leading to early failure. Conductive Concrete:

- Is non-corrosive and alkaline-stable

- Forms a protective layer around the electrode

- Maintains low resistance and physical integrity for decades

Many chemicals used in earthing:

- Contaminate groundwater

- Violate CPCB and environmental norms

- Are banned in several EU countries

✅ Conductive Concrete is inorganic, non-toxic, and leach-proof — future-ready and compliant with sustainable infrastructure mandates.

Many MNCs like Siemens, GE, Schneider, Amazon (AWS), and Tata Power Solar are demanding certified conductive concrete earthing for their Indian sites — aligning with global safety practices and internal ESG mandates.. This is causing others to follow the leaders — future-proof your infrastructure with globally accepted grounding or earthing material.

When dealing with any supplier, you should ask for:

- Certificate of Conformity / Test Reports: Show independent lab test giving resistivity, compressive strength, non‑corrosive chemical profile.

- Material Safety Data Sheet (MSDS): To check chemical inertness and potential harmful contents.

- Standard compliance documents: IEC / IS / BS EN certificates, etc.

- Manufacturer / brand authorization documents: If it’s a distributorship of a brand.

- Warranty / life guarantee documentation (something like 50 years, maintenance free).

- Case studies / Performance Reports from customers, with real measured resistance values over time.

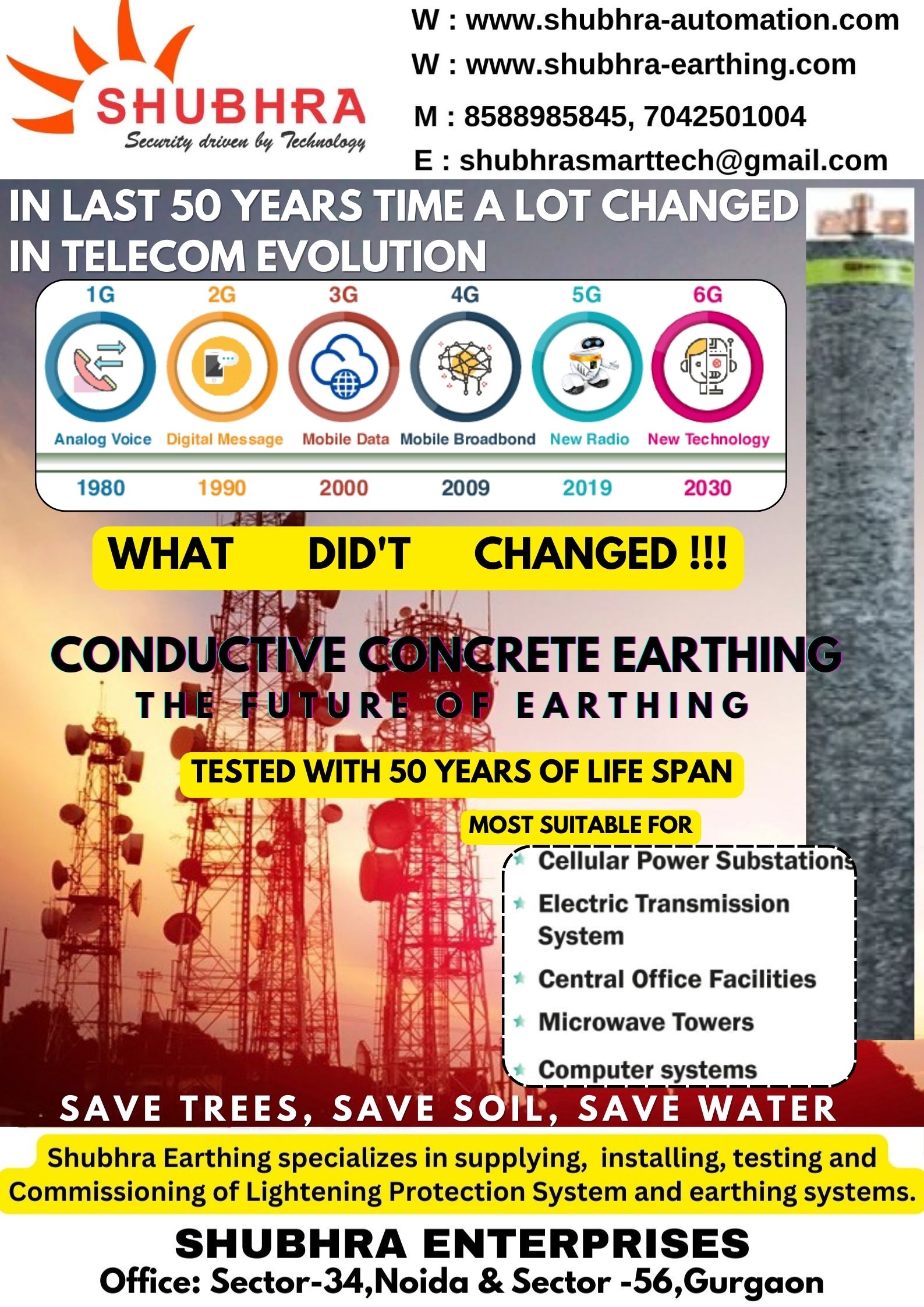

Earlier, India’s per capita electricity consumption was minimal — mainly limited to 1 fan, 1 bulb, 1 TV per household. The load was low, and the risks seemed limited.Earthing was treated as a formality, not a functional safety system.

India’s electricity usage has increased between 2006-07 and 2022-23: Per capita electricity consumption increased by 98%.

. Today, the average household and infrastructure use:

- Air Conditioners

- Inverters and Batteries

- Computers and Servers

- Electric Vehicles and Chargers

- Smart Appliances and IoT Devices

- Sensitive Electronics in Offices, Hospitals, and Industries

Each of these demands stable voltage, clean ground, and proper fault handling — all of which depend on effective earthing.

- Electrocution deaths (India has the highest among G20 nations)

- Electrical fires in homes, malls, EV stations, hospitals

- Failure of ELCBs, surge arrestors, and lightning protection systems

- Malfunction of IT/medical equipment due to ground noise or high resistance

- High legal, insurance, and reputational risks for organizations

A modern earthing system must be:

- 🔧 Designed based on soil resistivity and fault level

- 🧪 Installed with certified, inert, and tested conductive material

- 📉 Able to maintain stable resistance over decades

- 🛑 Corrosion-free, chemical-free, and maintenance-free

- 🧾 Documented with test results and compliance certificate

Thanks to:

• 🏢 Stricter safety regulations in PSUs and Corporates

• ⚡ Electrical consultants getting educated

• 📊 Real-world failures in poor earthing

• 🌐 Smart grid, EV and renewable energy adoption —

- Educate stakeholders — especially non-electrical decision-makers

- Bust myths with facts, test reports, and case studies

- Use certified products with proven life and performance

- Avoid duplicate or fake materials being sold as ‘cheap alternatives’

- Insist on testing, documentation, and performance guarantees

Because a modern power-hungry India can no longer afford:

- Outdated practices

- Unsafe shortcuts

- Poor-quality materials

- Ignorance about safety fundamentals

A single fault current, if not properly grounded, can kill, burn, or destroy.

Proper earthing is not an expense — it’s a lifeline for the new electric India.